SUMMARY

PLC Password Unlock like Siemens: S7-200 CPU 221, S7-200 CPU 222, S7-200. @Siemens, Omron, Mitsubishi, LG, DELTA PLC also touchscreen HMI. Kernel Access Password Recovery tool is a Microsoft Access MDB password recovery software designed to recover lost and forgotten passwords from Microsoft. Providing you the best range of Mitsubishi PLC Password Crack, Delta PLC Password Crack, FATEK PLC Password Crack, S7 200 PLC Password Crack, Delta DOP Series Project Password Crack and Allen Bradlley Micrologix & SLC Series PLC Password Crack with effective & timely delivery.

ICS-CERT is continuing to coordinate with Siemens concerning vulnerabilities affecting Siemens SIMATIC Programmable Logic Controllers (PLCs). In May of 2011, security researcher Dillon Beresford of NSS Labs1 reported multiple vulnerabilities to ICS-CERT that affect the Siemens Simatic S7-1200 micro PLC as reported in ICS-ALERT-11-161-01. The replay attack vulnerabilities affecting the S7-1200 also are verified to affect the SIMATIC S7-200, S7-300, and S7-400 PLCs. Siemens PLCs configured with password protection are still susceptible to a replay attack.

Commands between the affected PLCs and other devices are transmitted using the International Organization for Standardization Transport Service Access Point (ISO-TSAP) protocol. According to ICS-CERT analysis, the ISO-TSAP protocol is functioning to specifications; however, authentication is not performed nor are payloads encrypted or obfuscated. Like ISO-TSAP, many protocols used in industrial control systems were intentionally designed to be open and without security features.

ICS-CERT will publish additional information as it becomes available.

IMPACT

An attacker with access to the PLC or the automation network could intercept the PLC password and make unauthorized changes to the PLC operation.

The full impact to individual organizations is dependent on multiple factors unique to each organization. The ICS-CERT recommends that organizations evaluate the impact of these vulnerabilities based on their environment, architecture, and operational product implementation.

MITIGATION

ICS-CERT continues to work with Siemens to develop specific mitigations for the reported vulnerabilities.

The following mitigations can be implemented to reduce the risk of impact by the reported vulnerabilities:

- ICS-CERT and Siemens recommend that asset owners/operators apply a properly configured strong password to each PLC. Changing this password frequently and using unique passwords, when possible, will reduce exposure to this vulnerability.

- Defense-in-depth strategies for both enterprise and control system networks; see the ICS-CERT Recommended Practice document, Improving Industrial Control Systems Cybersecurity with Defense-in-Depth Strategies and Siemens’ Industrial Security website for more information on how to apply these measures.

- Siemens recommends that concerned customers block all traffic to the PROFIBUS, MPI, and PROFINET protocol-based devices from outside the Manufacturing Zone by restricting or blocking Ethernet access to 102/TCP and 102/UDP, using appropriate security technology.

- Restrict remote access to enterprise and control system networks and diligently monitor any remote connections allowed; employ Virtual Private Network for any remote system connections.

Siemens has published a document regarding the vulnerability affecting the SIMATIC S7-200, S7-300, S7-400, and S7-1200 products.2

ICS-CERT will release information concerning additional mitigations as they become available.

FOLLOW-UP

ICS-CERT published a follow-up advisory titled ICSA-11-223-01 - Siemens SIMATIC PLCs Reported Issues Summary on the ICS-CERT Web page on August 21, 2011.

- 1. NSS Labs, http://www.nsslabs.com, website last accessed June 10, 2011.

- 2. Potential Password Security Weakness in SIMATIC Controllers, http://support.automation.siemens.com/WW/view/en/51401544, website last accessed July 5, 2011.

Contact Information

For any questions related to this report, please contact the CISA at:

Email: CISAservicedesk@cisa.dhs.gov

Toll Free: 1-888-282-0870

For industrial control systems cybersecurity information: https://us-cert.cisa.gov/ics

or incident reporting: https://us-cert.cisa.gov/report

CISA continuously strives to improve its products and services. You can help by choosing one of the links below to provide feedback about this product.

This product is provided subject to this Notification and this Privacy & Use policy.

SIMATIC S7-200 is one of the popular programmable logic controllers in Siemens family. They are widely used because of their handy framework and easy operational interface. They also support a variety level of automation devices for industrial automation applications, which makes this device very popular.

It is also a siemens primary series programmable logic series controller because of its easy user interface. At the same time, it also provides more complex automation supports. The CPU fo this series microcontroller takes input logic and provides outputs which is control by the user program interface.

The program interface supports simple as well as complex math operations, boolean logic, counting, timing, and communication with other intelligent devices. This simplicity at the same time; its complex operations makes this S7-200 is a perfect solution for your task.

Now we discuss the most crucial part of the S7-200 PLC and their applications.

The CPU of the S7-200 series programmable logic controller combines with a very powerful microprocessor. It has a power supply, input, and output circuits, and its compact design creates this series a powerful Micro-PL C.

Siemens also offers different kinds of CPU for this S7-200 series, which helps you to chose the perfect PLC device for your variety level of applications.

Now we discuss different types of CPU available for the S7-200 series programmable logic controller.

The physical size of this CPU is 90x80x62 mm, which provides 4096 bytes program memory and 2048 bytes data memory. It also has six digital, analog input, and four digital-analog output.

It also offers high-speed counter in single-phase(4 at 30kHz), two face(2 at 20kHz), but unfortunately, no extension module is available for 221-CPU based programmable logic controller.

The physical size of this CPU is 90x80x62 mm, which provides 4096 bytes program memory and 2048 bytes data memory. It also has eight digital inputs and six digital output with 50 hours memory backup.

It also offers high-speed counter in single-phase(4 at 30kHz), two face(2 at 20kHz) extension module is available for these types of CPU controller.

The physical size of this CPU is 120.5x80x62 mm, which provides 48192 bytes program memory and 8192 bytes data memory. It also has 14 digital inputs and ten digital output.

It provides high-speed counter in single-phase(6 at 30kHz), two face(4 at 20kHz), and seven different extension module is available for 224-CPU based PLC.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The physical size of this CPU is 140x80x62 mm, which provides 12288 bytes program memory and 10240 bytes data memory. It also has 14 digital, two analog inputs, and 10digital, one analog output. It also provides high-speed counter in single-phase(4 at 30kHz), two face(2 at 20kHz) 7 different extension module is available for 224-CPU based PLC.

The physical size of this CPU is 190x80x62 mm, which provides 16384 bytes program memory and 10240 bytes data memory. It also has 24digital input and 16 digital output.

It also offers high-speed counter in single-phase(6 at 30kHz), two face(4 at 20kHz), and seven extension module available for this series types of CPU.

To solve your wide variety of applications in S7-200 series PLC provides a lost of expansion module. The module is easily fit on the main modules CPU and increase additional facility of your automation task. Here some of the expansion module available for the S7-200 series Programmable Logic Controller.

Discrete Module

- Analog Module,

- Intelligent module & some other modules.

The STEP 7-Micro/WIN programming package provides the most user-friendly programming environment to develop, monitor, and edition opportunity for your control system. The TEP 7-Micro/WIN provides three programming editor, which is very user-friendly.

It has very high efficiency in developing the control program for your applications. Again this programming packages also offers an extensive online help system and much documentation such as user manual, application tips, and tricks.

More significantly, CD, which contains all the electronic system and information of this type of PLC. These programming packages easily install your computer, and the requirements fo installation is mostly available on this modern type computer.

The installation process of STEP 7-Micro/WIN is quite easy as like other programming software. First, you need to run the CD into the CD-ROM of your computer.

The installation wizard starts automatically and guides you through the installation process. I also refer to read the remade file available in the installation, which provides you much more information about the install process of STEP 7-Micro/WIN.

Siemens provides two types of programming communication option for the S7-200 series programmable logic controller. A communication processor (CP) card with M P I cables and other one is a direct connection through a PPI Multi-Master cable.

P P I Multi-Master cable is most widely used for programming because it is very economical, and connection process through this cable is straightforward. Sometimes it also useful to connect other communication devices to the S7-200.

Text display (TD) is an external display device that can be connected through the cable to the S7-200. You can easily program your PLC to display text messages and other data processing by using this display.

This display also provides you a low-cost interface to allow you to view, monitor, and change the process of your applications.

OP 3micro and TP 177micro panels provide Siemens S7-200 PLC to operating and monitoring function for small scale machines and plants within short configuration and communications times.

Display panels supports almost 32 types of different language and five different online style, including Asian and Cyclic character sets for communication and configuration maintenance.

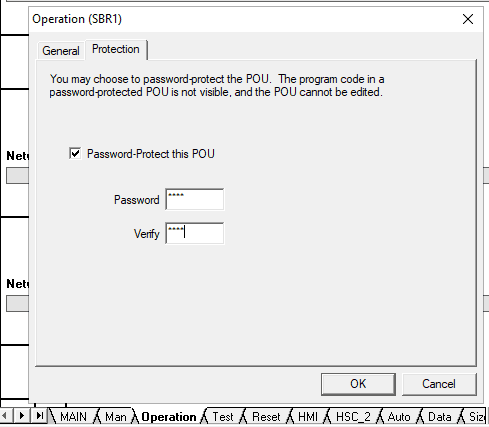

To unlock POU Password S7-200 smart use step7 MicroWIN Smart. The control program for an S7-200 smart CPU consists of the Program Organizational Unit(POU); those are Main program, Interrupt routines, Subroutines.

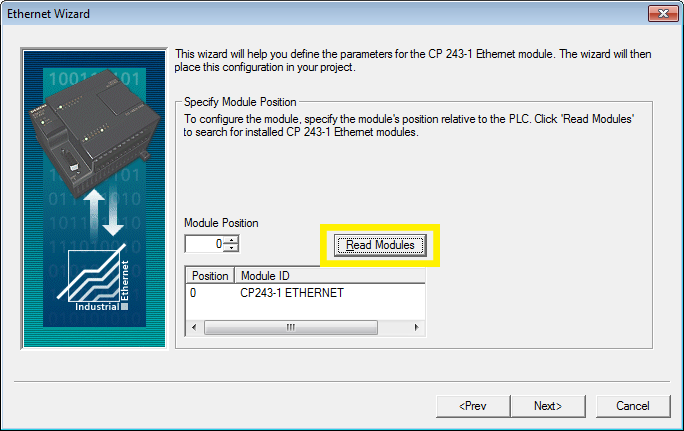

First, set a POU Password: Step7 Micro/WIN smart use ribbon tab user interface(the same as Microsoft Office). It helps users to find and use command efficiently. You need to download step&Micro/WIN. Then to set a POU password, please flow the steps:

Source link: https://365electricalvn.com/download-365evn/

S7 200 Plc Password Remover Reset

Now I discuss the process in several steps.

Siemens S7 200 Plc

Open the project with Step7 Micro Smart Program then click on the File tab→POU→protection

- Select password protect this box and then type character ‘Password’ and ‘Verify’(same values)

- Then click ‘OK’ and close, save the project to apply the password.

Now, to see the code and edit program, we need to unlock the POU password S7-200 Smart

check the Step7 MicroWIN Smart Version on your personal computer. NB: this tool only supports the version V2.0 or V2.2

- Download the tool Unlock POU Passwords S7 200 SMART at the end of pos.t

- Open the path: “CProgram FilesSiemensSTEP7-MicroWIN SMART’. Rename file ‘data managers.dill’ to ‘data manager-backup.dill.’

- Now extract the download file and copy file ‘data manager V2.x.dill’ to Program FilesSiemensSTEP7-MicroWIN SMART and rename the file ‘data managers V2.x.dll’ to ‘data managers.dill.’

- Open the project. It would be best if you unlocked POU passwords S7-200 smart.

Simatic S7 200

S7 200 Smart Plc Software

Siemens S7-200 another most popular choice for starting programming, and it is also one of the cheapest PLC from Siemens, and it is very easy to programming. Though Siemens S7-200 has a limited variety of function but certainly it has many advantages.